Below are examples of 12 6 and 3 2mm 1 2 1 4 and 10ga mild steel cut with oxygen on a 2kw fiber laser and examples of the same part cut with 1 variable changed to show how it affected the cut quality.

Mild steel laser cutting speed chart.

Different fiber optics material quality gases optical lenses cutting patterns etc will affect the cutting speed and need to be adjusted according to site conditions.

Co 2 lasers use an electromagnetically stimulated gas typically a mixture.

All cutting tools have a recommended cutting speed for any given material.

So too can carbide and ceramic cutting tools achieve higher speeds regardless of the workpiece material than do ones made of high speed.

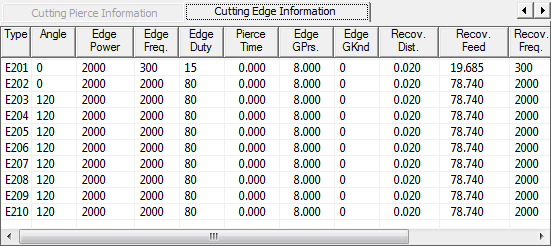

Factory cut chart settings.

Table 3 recommended cutting speeds for drilling with high speed steel drills.

If you d like to learn more about ablative laser cutting check out this article on micron scale manufacturing.

The following data in the laser cutting thickness speed chart is for reference only.

In table 3 you will find a typical recommended cutting speed chart for drilling.

Given its dominance in the sheet metal cutting industry this article focuses on laser fusion cutting.

These charts can be found in the machinery s handbook textbook or a chart given to you by your tool salesperson.

Milling drilling reaming top.

Milling drilling and reaming with these charts and cutting speed calculators.

Fiber lasers vs co 2.

The examples of the adjustments made will be similar for any co 2 or fiber laser cutting mild steel with o 2.

Fiber laser cutting thickness speed chart.

Recommended cutting speeds are given in charts.

Chart 3 illustrates the different efficiencies for the various cutting lasers.

The differences in the operating cost are based on the maintenance and the efficiency of the style of laser being used.

The final piece of the puzzle for laser processing is the cutting speed.

The two most common types of laser cutting machines are fiber laser and co 2.

Softer metals like aluminum and mild steel have higher cutting speeds than do nasty metals like titanium or inconel.

Thickness mm ipg 1000w ipg 1500w ipg 2000w ipg 3000w ipg 4000w ipg 6000w ipg 8000w ipg 10000w ipg 12000w ipg 15000w.

Factory cut chart settings the following show 12 6 and 3 2 mm 1 2 1 4 and 10ga mild steel cut with oxygen on a 2kw fiber laser and examples of the same part cut with 1 variable changed to show how it affected the cut quality.